News

Condition monitoring

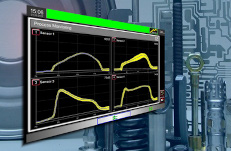

Machine Condition Monitoring is an integral element when it comes to the issue of preventive maintenance. As an addition to our proven load monitoring systems, Condition Monitoring offers a comprehensive look into the „health“ of your machinery.

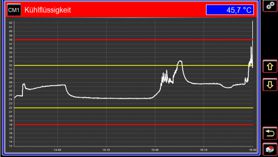

Sensors for measuring criteria such as temperature, pressure, vibration, energy and compressed air consumption or other important machine parameters can be directly connected to the existing process monitors to permanently register the current status of the machines. Adjustable warning and stop limits ensure that your production processes are protected reliably and that unnecessary down time is avoided. The optional long term archiving keeps you informed if and how the measured values change over time e. g. due to wear and tear effects.

Automated Condition Monitoring is an important step toward Industry 4.0, and is considered a key element by many auditors for high quality and reproducible manufacturing processes. Machine Condition Monitoring supports producers in complying with the requirements of IATF 16949.

Would you like more information? We would be happy to present you the possibilities of the new condition monitoring.