Testimonials

Life of Thread Rolling Dies Increased Five Fold!

We never would have expected such an increase in die life without sacrificing product quality” says Olaf Ambros who is the cold forming expert and R&D manager at baier & michels which is part of the WÜRTH-group. They had ordered an Schwer + Kopka system to equip a Saspi GV2 thread rolling machine with the latest monitoring technology. The machine produces a special thread form which requires custom designed, expensive rolling dies. “In the beginning, we expected a tool life of maximum 300,000 pieces. Imagine how excited we are now where we regularly produce up to 1.5 million pieces out of a set of dies” explains OlafAmbros of the extraordinary results.

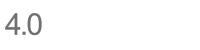

It is important to reproduce good machine set-ups which previously resulted in good thread quality, using the lowest amount of force on the dies. Schwer + Kopka's thread roll monitoring systems offer innovative techniques such as DMI (die match indicator) and Part Data Memory which stores the force curves on all 4 adjusting points of the die block. The experts of baier & michels use these features extensively to get in-depth views into the forming process and improve die settings.

Olaf Ambros adds: „Repeating good die set-ups is the most important aspect to achieve long tool life. The Schwer + Kopka process monitoring system enables us to repeat optimum die set-ups,even when we use the dies for several production runs. The obtained savings are impressive and worth every cent of the nvestment. In the meantime, we have equipped more machines with process monitoring systems by Schwer + Kopka!”