MES Terminals

The machine terminal is the central communication device for the entire data exchange between the machine and MES. It is also a comprehensive information control center for the machine operator. The terminal collects all performance data of the machine such as runtimes, downtimes, downtime reasons, cycle rates, manufactured quantities and much more and transfers them to MES.

In return, it informs the machine operator about upcoming jobs and parts with target quantities, planned cycle rates and, if necessary, further information and documents such as drawings, quality notes, set-up values, shift transfer protocols, etc.

Our terminal program ranges from cost-efficient compact devices with 4.3" touch-screens to PC-based terminals with currently 10" and 15" screen sizes.

MES Terminal SK 200T

Low cost, very compact Touch-Screen Terminal

- for single machines

- 4.3" color screen with touch-screen

- Ethernet connection or optional W-LAN

- 2 inputs for machine signals such as pulse, operation mode or cycle

- 2 outputs e.g. for machine interlock or indicator light

- optional barcode connection

- dimensions just 150 x 100 x 35 mm (W x H x D)

Terminal Functions:

- job start/finish/interrupt

- job speedo with tickerband

- part counter, scrap recording

- input of down codes

- personnel login/logoff

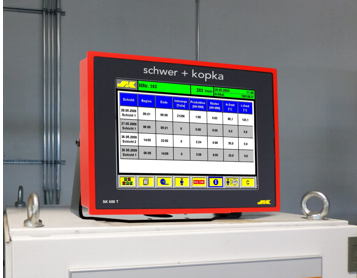

MES Terminal SK 600T

Compact Touch-Screen Terminal

- for single machines and groups of up to 32 machines

- 10.4” color monitor with touch-screen

- fanless PC with Windows 10

- Ethernet connection or optional W-LAN

- optionally integrated RFID reader

- optional count module for direct connection of up to 4 machines

- serial interface for readers

- USB interfaces

Terminal Functions:

- job start/finish/interrupt

- job speedo with tickerband

- part counter, scrap recording, batch change

- input of down codes

- personnel login/logoff

- tool consumption (list)

- editing maintenance jobs

- creating repair jobs

- message transfer (graphic)

- display of PDF documents

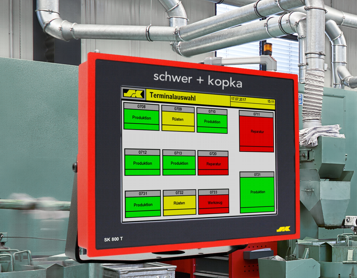

MES Terminal SK 800T

Highend Terminal with large Touch-Screen

- for single machines and groups of up to 64 machines

- 15” color monitor with touch-screen

- fanless PC with Windows 10

- Ethernet connection or optional W-LAN

- optionally integrated RFID reader

- optional count module for direct connection of up to 4 machines

- serial interface for bar code readers

- USB interfaces

Terminal Functions:

- job start/job finish/job interruption

- job speedo with tickerband

- part counter, scrap recording, batch change

- input of down codes

- personnel login/logoff

- tool consumption (list)

- editing maintenance jobs

- creating repair jobs

- message transfer (graphic)

- display of PDF documents