MES Modules

The MES software SK-go!® is a comprehensive, module-based system for all tasks of data acquisition in the production area. The carefully coordinated modules ensure the necessary consistency of data in all areas. This makes SK-go!® an important component for the implementation of Industry 4.0 projects.

Each module can be individually combined to different expansion stages according to your requirements. The "Tachograph" expansion stage offers a particularly simple and cost-effective "gentle introduction" to the world of production data acquisition. Or you decide for a quick access by recording the data for the calculation of OEE factors. The next stage complements the recorded production data by down time codes and connects them with the finished work orders and products. An extension of your system to the next expansion stages is possible at any time.

A comprehensive software service package makes sure that your system is permanently maintained and kept up to date. Our telephone hotline supports you in all questions concerning the use of your system. Competent employees help with technical questions and problems via remote maintenance or personally on-site at your premises.

- Benefits:

- Targeted notifications in case of problems

- Reduction of reaction times

- Implementation of escalation scenarios

- Live Info worldwide

With MES Controlling, Process Controlling and Mandonmanager 4.0 you have 3 instruments available which inform you quickly about critical events. Be it in form of a red traffic light in the machine overview, a highlighted machine while scanning the machine park, or by specifically notifying the right persons by e-mail or SMS.

You define individually which criteria should trigger an alarm, e.g.:

- Degree of utilization drops below a certain limit

- Machine stops for more than xx minutes

- current job expires in xx minutes

- Machine has no scheduled follow-up order

- Reject rates greater than xx percent

- and many further critical queries

In this way, you recognise problems when there is still the possibility to act, and not only during the review of the recorded data! Your "electronic works tour" and the quick reaction reduce plant downtimes, optimise machine performance and avoid losses.

Close...

- Benefits:

- Transparency in the entire production process

- Online Info Center for all employees

- Employee motivation

- Better machine utilisation

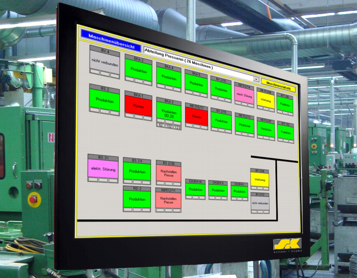

ANDON is a visual management method developed by Toyota in Japan to make processes and functions of production plants transparent and accessible to everyone. Originally, simple indicator lights were used for this purpose. Today, large screens are used which are clearly visible in the various operating areas.

The ANDON-Infocenter of SK-go!® shows on easily readable, comprehensible graphics whether and in which way the machines of the department are currently working. The displays inform on the services provided so far, such as quantities, OEE factors, average setup times and other details. It is visible to everyone whether and where help is needed due to which disturbances.

In addition to the available standard displays, the contents of the ANDON displays can be specifically adapted to the user's requirements by using a configurator.

Close...

- Benefits:

- Fast detection of critical products

- Weak point analysis per article

- Product comparison

- Automatic response to ERP

All relevant order data is taken over through interfaces of your ERP and forwarded directly from SK-go!® to the planned machine terminals. The machine operator knows directly which orders are pending with which products in which quantities and at machine cycle rate. he should run the machine. He starts the current next order from the displayed backlog of orders and finishes it after completion. SK-go!® reports the performance data and the work progress to ERP at regular intervals and also at the end of the order.

The current and the completed orders can be evaluated specifically with regard to:

- Job analysis of usage, down codes, quantities, OEE factor, etc.

- Existing order backlog and planned order sequences

- Tabular and graphical order comparison (which machine is most suitable for a certain article)

- Down code statistics and runtime behavior

Batch recording

Document the use of your material batches completely and transparently!

- Benefits:

- Documentation of the batch used

- Traceability for each order

- Evidence to the customer

- Inspection of the material batch to be used

In many areas it is required to provide complete evidence of the batches of material used for each production order. For this purpose, simply enter the batch number when registering the order at the SK-go!® machine terminal or scan it from the batch accompanying label using a barcode reader. If available, SK-go!® asks the ERP system whether this batch has been released for the current order. If desired, the machine remains locked if the batch input is missing or an unreleased batch has been registered.

Now you always have proof of which batch(es) was (were) used for an order. In the event of a complaint, it is quickly evident whether and which further orders were produced with the complaint batch.

Close...

- Benefits:

- Paperless production

- Online access to important documents

- Always available in current version

- Terminal as central Info point

Even in the age of Industry 4.0, paper is still widely used in many manufacturing processes. Even in the harsh environment of production machines, there is always a drawing of the finished product, a machine setting plan, a quality reference as well as the accompanying documents of an order. At this point, besides the problem of contamination of the documents, the question of revision safety always arises. If a document has been modified, all versions in production must be laboriously replaced.

By connecting the MES software SK-go!® to the document structure, documents can be retrieved in PDF format or as graphics directly at the machine terminal. Now all required documents are available online in current revision at the machine anytime. Furthermore, the machine operator is informed which documents are stored for the current job. If desired, it has to be recorded that the documents were also viewed.

Consistently implemented, paperless production can be reality!

Close...Energy Management System

Identify energy-saving potentials with the detailed recording of real machine consumption!

- Benefits:

- Implementation according to DIN ISO 50001

- Avoidance of expensive peak loads

- Detection of energy guzzlers

- Determines characteristic values such as consumption per unit

With the SK-go!® module EMS you not only record the actual energy consumption of individual systems, but also assign them clearly to the respective machine status. This allows you to quickly identify where energy guzzlers are located, where saving potentials can be exploited and where energy is wasted unnecessarily that is not actually needed at all.

The energy cockpit always shows you the current consumption and warns you if predefined, critical consumption limits are reached. This enables you to control your systems in an energy-efficient way and you avoid being upgraded to more expensive tariffs by your energy supplier in the case of impermissible maximum consumption.

With EMS you can identify saving potentials and optimise your operating costs. The permanent recording of consumptions, their documentation and monitoring are some of the conditions for fulfilling the requirements of ISO 50001.

Close...Successful certifications with modern process monitoring and ProAudit

Make your auditor happy! Seven steps to a successful certification.

- Benefits:

- Transparency in every certification

- Online documentation available to everyone

- Paperless evidence

- Consistent implementation of the quality concept

Companies in the supply industry are continuously tested through regular audits. They have to prove how the required quality standards are observed. It is good if modern process monitoring systems are already in use on the production machines. This ensures the quality during the running process!

But what do you say to the auditor's following questions:

- Are your process flows precisely documented?

- Are your machines maintained properly?

- Are you working with reproducible setting parameters?

- Are only authorized employees allowed to make relevant changes?

- Are the target values checked regularly?

- Are the SPC inspection intervals consistently observed?

- Are you really able to prove compliance with all measures?

The ProAudit concept uses our long-standing expertise for repeatable, controlled manufacturing and lays the foundation for successful further audits. In 7 steps, we support you in the right way to score points in the next customer audit by consistently implementing measures to improve quality.

Close...

- Benefits:

- Consistent data flow

- Automated feedback strategies

- Avoidance of incorrect entries

- Always current level of information

An important function of MES is the feedback of live production data to the superordinate ERP system via suitable interfaces. Our MES software SK-go!® has ready-to-use interfaces to most of the common ERP systems, which are used by many different customers in their daily work. From SAP to Infor, TimeLine to Sage, ABAS to Pro-Alpha and many more - every ERP system can be linked with SK-go!® without great effort. Our interface configurator allows us to realise the quick and easy exchange of data with other ERP systems and also with customer-specific, individually programmed applications.

The interface also ensures regular feedback of order-related performance data and order progress to the ERP system. This guarantees the necessary data flow in both directions. Manual input with subjective data is a thing of the past.

Close...Facility Manager

The last one turns out the lights! This or something similar is the brief description of the facility manager.

- Benefits:

- Reduction of operating costs

- Needs-based requirement

- Extension of unit downtimes

- Avoidance of energy waste

With the MES software SK-go!®, all auxiliary and supply units as well as energy consumers in production can be controlled as needed. For this purpose, we use an aggregate server via which the connected systems can be switched on or off on demand. For example in many production facilities, the exhaust air locks available for each machine are only open when the machines are actually in production. If a machine is not in operation, the airlock is automatically closed after an adjustable waiting time. Thus, the compressor has to generate less air volume and uses less energy.

The compressed air supply itself can, for example, be switched off completely or line-by-line in an unmanned trailing layer after the last machine has been stopped. Unnecessary air consumption through open valves (leakage losses) is avoided.

For this purpose, the auxiliary units can be controlled by time. The desired unit automatically boots before the start of the first shift scheduled on the respective day and switches off after the end of the last shift.

Close...Linking MES to CAQ

Never again forget SPC inspections and never let unnecessary inspections take place!

- Benefits:

- No double order registrations

- Never forget an exam again

- Avoid unnecessary inspections

- Machine stop in the absence of an inspection

- Proof of compliance with the regulations

The linking of SK-go!® to your CAQ system ensures that SPC inspections are only initiated when they are actually due. Up to now, fixed inspection intervals were prescribed, now the inspection period is only dependent on the actual running time of the machine recorded in MES or rather on the number of the parts produced. The data exchange of MES with your CAQ system via interface provides decisive advantages:

- Job start in MES also starts the inspection order in CAQ

- At his machine terminal, the operator is requested to perform each due SPC inspection including the first piece inspection.

- If desired, the machine can be stopped in the event of delayed inspection and in case of NOK measurements

- Then the release of the machine only takes place after further inspection of the goods.

- Additional inspections are initiated after certain stop reasons (e.g. tool change) and after a period of machine downtime.

SK-go!® documents the machine running times and inspection points together. In case of critical queries, e.g. as part of audits, you can immediately prove that the test specifications have been consistently observed.

The MES software SK-go!® offers field-tested interfaces for many leading CAQ systems such as Babtec or Böhme & Weihs.

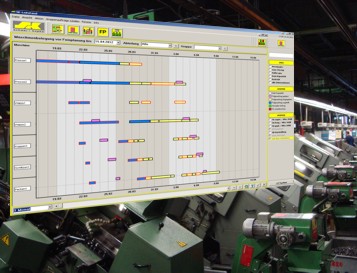

Close...Control station with job distributor

Optimally distribute orders within a short planning horizon to the available machines!

- Benefits:

- Simple planning by drag & drop

- Optimised order sequence

- Setup optimisation

Let your group or team leaders the freedom to optimally schedule orders within a short planning horizon to the available machines without having a negative influence on the delivery date. With the job distributor of the SK-go!® job center, you can use Drag & Drop to move orders quickly and easily from the work list to a suitable machine or reschedule them from one machine to another.

The job center visualizes the current deadline situation online and calculates delays or advances based on the progress data of the currently running orders from SK-go!®. MES and job center work hand in hand. Initially, all rescheduling takes place virtually, with specification of the resulting schedule. Only when you are satisfied with the results you import the new job sequences to MES and automatically forward the job data to the corresponding machine terminals.

Furthermore, the job center supports you with the following functions

- Visualization of capacity utilization

- Visualization of the sequence of operations

- Determination of alternative machines based on existing data

- Benefits:

- Online status request of all machines

- Live monitoring of production

- Automated status detection

- Objective, tamper-proof data

Machine data is the lifeblood of MES, because it determines the efficiency and performance of production systems. Important data such as up and downtimes, quantities produced and cycle rates usually can be tapped easily from the existing machine controls or can be recorded via sensors. Further data, e.g. reasons for downtime, are assigned by manual messages at the machine terminal. The following evaluations of the machine data are available:

- Shift protocols

- Error analyses

- Runtime behavior

- Machine performance

By the way: with MES we not only record real production machines, but also various auxiliary systems and aggregates such as

- Sorting Machines

- Packaging plants

- Heat treating ovens

- Coating plants

- Washing machines

- Compressors

- and several more

MES machine terminals

Choose your suitable model from our MES terminal program. All of them are built for usage in harsh industrial environments.

- Benefits:

- Data collection directly at the machine

- Different sizes, depending on application

- Robust and low-maintenance

- Simple operation

schwer + kopka manufactures a wide range of MES machine terminals. They are built in-house for the use in industrial applications. From the simple low-cost terminal to the comfortable touch-screen device with 15" display for highest graphical demands, our offer provides the suitable recording level for all needs. The terminals automatically determine the important machine data such as up times, downtimes, quantities produced and cycle rate based on the quantity impulses of the connected machines. For this purpose, the terminals offer suitable inputs

We also supply an extensive range of MES terminals with integrated process monitoring functions. They offer tailored solutions for production plants such as stamping machines, forming presses, thread rolling machines and cutting machines, lathes and drills or for joining and assembly processes.

Our large-sized ANDON information boards or the work-centered ANDON client workstations provide fast information in the production area.

Close...OEE key figures

Do you know whether your production works economically? Ask the OEE key figures!

- Benefits:

- Simple reporting

- Key figures at the touch of a button

- Consistent reports

- Good comparability of plants and factories

In many places, the OEE key figures are an indispensable component for assessing the efficiency of production plants. The OEE is also used internationally in order to compare economic competitiveness.

The so-called "Overall Equipment Effectiveness" (OEE) is a percentage number and is calculated by multiplying the following single shares:

- Availability (how long has the plant been in production and how long has it been inoperative?)

- Performance efficiency (has the plant operated with the required output per unit of time?)

- Quality grade (quantity produced less the share of rejects during the period under review)

SK-go! has all the necessary data available and calculates the OEE factor and its components on-line. The calculated values are automatically provided in numerous of the available evaluations.

Close...

- Benefits:

- Scorecards at the touch of a button

- Long-term view of key figures

- Comparison of individual machines

Scorecards provide key performance indicators of a production in easy-to-use overviews. With the PAS (Production Analysis System) module, you can quickly and simply analyse all key figures over freely definable periods of time and machine selections. So tendencies can be recognised, but also correlations with other key figures become apparent.

Typical key figures for scorecards are the performance values of the machines such as OEE, degree of utilization, performance efficiency or the number of pieces produced, but also the times incurred in the respective operating modes such as production, set up or downtime.

With just a few clicks, you can create the right score card for your relevant question. If required, you can print it out and have the latest charts that can be posted on the notice board, for example.

Close...Personnel registration/deregistration

Collect the employee's distribution times on the various plants!

- Benefits:

- Assignment to the employee

- User-defined assignment of rights

- Shift planning on the PC

In addition to traditional time recording, by which an employee's attendance time is recorded, many companies want to visualize the employee's distribution times on the various plants. This is particularly the case for productions with multiple machine operation. With SK-go!®, individual employees can log in and out at the MES terminals by entering personnel numbers or by using an RFID chip. If desired, the machine is locked in the absence of personnel registration and is only released after successful registration. The attendance times of an employee at a machine or at a job are recorded and assigned accurately and transparently. Companies with performance-related pay require this information in addition to the objective, tamper-proof recording of machine performance data.

A customer-specific set of rules can be used to determine whether each machine is operated exclusively (only 1 employee) or by several employees, whether the successor automatically deregisters its predecessor, and in what form times are to be reported back to the superordinate ERP system. If there are any questions about a production section, the right contact person can be found quickly and easily thanks to employee registration.

If the entry of employee data is not permitted in your company due to company agreements, SK-go!® naturally works without this data and also does not offer access to it.

Close...Protocols

Create checklists in the simplest way, which have to be filled in at different times and occasions!

- Benefits:

- Online documentation of all checklists

- Forced running at the machine

- Reduction of manual input

- Standardisation within the inputs

- Comprehensive work record

Recurring work such as cleaning services and/or lubrication services, visual inspections, machine condition checks or minor maintenance work must be carried out on production machines. The complete documentation of the work is important, especially as evidence for external auditors or for the plant manufacturer.

With the "Protocols" module, checklists which the operator can or must fill in at different times can be created very easily. For example, you can create a checklist for the machine cleaning as well as for the cleaning of the workplace every Friday during the late shift. The operator fills them out online at the schwer + kopka machine terminal and verifiably confirms that the required work has been carried out. Instructions can also be deposited in the form of operating steps, e.g. for machine adjustment, whose processing must in turn be confirmed by the operator point by point and is thus checked off. The checklists can consist of simple yes/no queries as well as require the entry of numerical values, e.g. when checking machine bearing clearances.

The "Protocols" module can be linked to the "Maintenance" module. After each completed maintenance or repair order on the machine, the maintainer must fill in a prefabricated report and thus confirm that the prescribed work has been done.

Close...PTO 4.0 for 100% documentation of process data

Automatically archive all relevant process data in the network!

- Benefits:

- 100% process documentation

- Transparency to the customer

- Internal process analysis

- Optimised tool design

- More successful audits

- Supports the requirements of IATF 16949

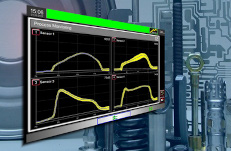

For the first time, our system PTO 4.0 (Process Tracking Office) allows a comprehensive, complete and automatic documentation of all relevant process data in the network. Now, even for fast processes in series production, you can provide complete proof that production has been carried out with high repeatability, process reliability and in a controlled way, even between the prescribed SPC sample inspections.

For this purpose, the installed process monitoring systems transfer all important data to the PTO server:

- each measurement or rather measurement curve according to the desired recording interval

- adjustment of monitoring accuracy and any change in settings

- each new teach-in of the setpoint curves

- all data of sorted parts

- all data of detected defetive parts and errors

- spread width/variation of the process

- up and downtimes with AUTO/TEACH-IN/STOP operating modes

A replay function with time lapse allows you to "replay" any batch afterwards so you can quickly detect inconsistencies. PTO 4.0 as a supplement to the classical sample tests such as SPC inspections finally closes the existing gap in documentation. In the event of customer complaints, you can provide comprehensive evidence of how the parts were actually manufactured. Internally, the data is used for targeted problem analyses.

Close...

- Benefits:

- Classification of downtimes

- Pareto analyses over arbitrary periods of time

- Identification of technical and organisational weak points

Every machine downtime usually requires the entry of a reason. Only by consistently recording the causes of downtimes you will be able to identify them!

In the case of a machine stop, the MES terminal automatically displays a list of down codes that you have defined for this type of machine. From the offered down codes the operator must inevitably select a reason, otherwise the machine is locked (optionally adjustable). For short stops, you define up to which downtime the entry of a code may be waived.

The resulting analyses of the down codes will show you precisely which reasons lead the "hit parade" for the machine or machine group under consideration. You will know exactly for which disturbances it is worthwhile to remedy.

You also decide which types of malfunction are relevant for OEE and which should not be included in the OEE calculation.

Close...View / ProcessControlling

Keep an eye on your process monitoring performance! Always know how well your quality is monitored.

- Benefits:

- Central function control of the monitoring devices

- Live view of the process

- Virtual tour through all machines

- Access to data in the event of complaints

Dial in online directly to any connected machine with a monitoring device and that from any PC in your network. SK-go!®-View makes it possible. This gives you access to all parameters and process data. Equipped with the appropriate user rights, you can even adjust the settings of the process force monitoring remotely.

The important monitoring parameters are archived on the SK-go!® server as part of the our ProcessControlling option and can subsequently be visualized and analyzed for of each produced order.

Close...

Tool storage management

Know where to find which tool and whether there are still enough in stock!

- Benefits:

- Tool stock always available online

- Cost savings by optimising the required quantities

- Transparent tool paths

With the tool storage management you can easily and uncomplicatedly establish different storage locations, from the central warehouse in tool making to the intermediate warehouse "machine". With the SK-go!® tool client, you make the appropriate storage allocations and withdrawals and thus follow the path of all tools through production. This way you always know how many tools are currently in circulation and where they are located.

Close...

Recording of tool consumption

Simple and accurate! Online recording of tool consumption directly at the machine terminal.

- Benefits:

- Prompt consumption data

- Direct collection on the machine

- Complete by forced input

- Overview of consumption per machine/order

Today, tools are often custom-made and therefore correspondingly expensive. In practice, only little attention is paid to the consumption of tools and thus to an accurate recording of an important share of production costs. The consumption of expensive tools is often only sporadically recorded in the form of incomplete hand-written records and is not always consistently evaluated.

With the tool consumption module, the MES software SK-go!® offers a convenient and, if required, force-controlled recording of used tools. Replaced tool parts are reported directly via the machine terminal or the process monitoring device. If "Tool change" is reported as the cause of a machine breakdown, the tool part list belonging to the product currently being produced appears automatically on the terminal screen in graphical or tabular form. From this, the machine operator simply selects the replaced part and thus reports back the consumption.

Close...Workshop overview + MES controlling

See and know at a glance what's going on in the company and what is not!

- Benefits:

- Virtual company tour

- Finding current problems online

- Signaling foreseeable events prematurely

- Live machine status

The workshop overview clearly shows the current state of production. The individual machine symbols can be arranged in size and position so that they reflect the actual hall layout. You create individual workshop overviews for each department and for the entire company. With the user administration you determine which employees have access to the individual areas. For each machine, SK-go!® provides comprehensive information on the current job-related performance data and on the machine performance in the last shifts, days, weeks and months.

The workshop overview provides information for each machine about:

- the current status and its duration

- the reported down code while the machine is inoperative

- data of the current job and its degree of completion (if the mouse pointer is on the machine)

- status of the 3 freely selectable warning lights for critical situations (e.g. degree of utilization has fallen below 50%)

- status of 3 freely selectable key figures (e.g. shift performance, degree of utilization, degree of performance)

With the MES controlling function, you can also check your entire machine park for critical situations and target attainment. You will receive direct answers to important questions such as:

- For which machines will the orders expire soon (adjustable time frame)?

- For which machines are no further orders scheduled?

- Which machines produce an above-average amount of rejects?

- Which machines have been inoperative for more than e.g. 1 hour (adjustable period)?

- Which machines produced more than the target quantity?

- Which machines do not comply with the prescribed cycle rates?

MES immediately alerts you if there are any deviations from the plan, so that you can still react in an affecting way!

Close...

Condition-based and preventive maintenance

Control due and preventive maintenance work via the actual machine running time!

- Benefits:

- Runtime and/or schedule-controlled work

- Recording of the required times

- Generation of repair orders at the terminal

- On-line evidence of work

- Supports the requirements of IATF 16949

Conventional maintenance applications are not capable of recording and planning the work that arises on a runtime-controlled basis. They lack information on actual operating hours. Only by linking with the MES data from the machine it is possible to carry out the desired maintenance work economically and at the right time. This caters for real condition-oriented and preventive maintenance. On the other hand, unnecessary work that is not yet due is avoided.

The MES-Software SK-go!® offers the maintenance tool which is linked to the machine data. Due work is planned and initiated according to schedule and/or runtime. An on-line to-do list informs the departments concerned about the current jobs. With the beginning of the work, the maintainer registers on-line at the terminal of the respective machine and receives further information about the type and extent of the maintenance. The completion of the work is also reported and, if necessary, a description of the activities carried out and the parts replaced is added. The required maintenance can be linked with an additional protocol. The maintainer has to check this off in the form of a checklist and thus documents the work carried out.

In addition to the scheduled maintenance, the machine operator can generate a repair order directly at the MES terminal in cases of emergency. Maintenance is immediately informed of an acute problem and can take action. The relevant persons are notified online by email or SMS.

Close...