Modules

PTO 4.0 for 100% documentation of process data

- Benefits:

- 100% process documentation

- Transparency to the customer

- Internal process analysis

- Optimised tool design

- More successful audits

- Supports the requirements of IATF 16949

Automatically archive all relevant process data in the network!

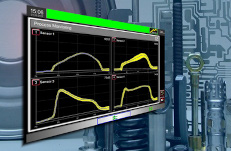

For the first time, our system PTO 4.0 (Process Tracking Office) allows a comprehensive, complete and automatic documentation of all relevant process data in the network. Now, even for fast processes in series production, you can provide complete proof that production has been carried out with high repeatability, process reliability and in a controlled way, even between the prescribed SPC sample inspections.

For this purpose, the installed process monitoring systems transfer all important data to the PTO server:

- each measurement or rather measurement curve according to the desired recording interval

- adjustment of monitoring accuracy and any change in settings

- each new teach-in of the setpoint curves

- all data of sorted parts

- all data of detected defetive parts and errors

- spread width/variation of the process

- up and downtimes with AUTO/TEACH-IN/STOP operating modes

A replay function with time lapse allows you to "replay" any batch afterwards so you can quickly detect inconsistencies. PTO 4.0 as a supplement to the classical sample tests such as SPC inspections finally closes the existing gap in documentation. In the event of customer complaints, you can provide comprehensive evidence of how the parts were actually manufactured. Internally, the data is used for targeted problem analyses.