Applications

Cold forming

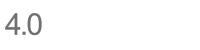

Process and tool monitoring systems have been part of the state of the art in forming technology (massive forming) for many years.

They ensure a consistent product quality of the formed components even at the highest production speeds and protect machines and tools against overload damage at the same time.

The various forming processes are monitored on every possible type of machine of the various manufacturers. Typical fields of application are single- and multi-die presses, boltmakers, nut formers, and special designs, which usually work from wire. Another focus is on machines used to roll the threads onto prepressed blanks in the fastener industry. Our systems also monitor further work steps such as thread tapping, trimming, secondary cutting operations, etc. Many machine builders are offering our process monitoring systems as factory fitted options on new and rebuilt machines.