Applications

Stamping Technology

Stamping, forming, drawing, bending, pressing, embossing, flanging, piercing, inserting bolts or nuts, cutting or forming threads – Stamping dies are becoming more and more elaborate as the demand for ever more complex products increased.

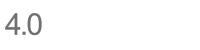

Modern progressive dies operate multi-stage and are combining numerous operations to produce a finished part requiring no other work steps. The increasing complexity not only made the dies more expensive, but also more prone to process errors. Faulty stampings as caused by punch breakage, cracked dies, feeding errors, rising slugs, rising stamping scrap, double material, crack formation on drawing edges, etc. not only threaten process reliability and product quality but often lead to serious die damage with a corresponding loss of production.

The modular design of our process monitoring systems in respect to the types of sensors that can be connected, the number of measuring channels as well as the freely configurable monitoring logics make our systems the first choice for various applications and measuring tasks. We supply adapted monitoring techniques for common faults and errors in stamping. Today, systems from schwer + kopka are in daily use on a wide variety of stamping machines and presses from all leading manufacturers.