Applications

Assembling / Testing

Today, many assembling operations demand a process-integrated, comprehensive monitoring of all relevant quality-determining parameters.

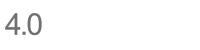

Suitable monitoring parameters are force/travel or torque/crank angle measurements. A good process is given, when the measured signals have reached certain end values, have passed through defined control windows, or fit into tight envelope bands. This is the only way to ensure that each individual operation has been carried out with the specified target values and thus meets the quality requirements. Our modular system was especially designed for the requirements of the assembling and testing industry.

Up to 128 different production processes can be monitored with one system in a network. The processes can run synchronously and asynchronously. Monitoring is carried out in free combination of the proven monitoring windows and the dynamic envelope technology. The system can be linked with central servers for documentation purposes and furthermore, are characterised by an easy handling. Typical applications include press-fitting, assembling, riveting operations, flanging, bending, rolling and monitoring of test operations.

A special application is clinch monitoring which is frequently found in the sectors of car body manufacturing or white goods. Special monitoring programs are available for this purpose, which includes amongst other things the remaining bottom thickness as the most important quality feature. A measuring program memory ensures that the appropriate parameters for each joint are checked in the correct sequence for each material pairing. That applies to complex processes such as clinching a car body part made of several sheets with adjusted thicknesses and strengths (so-called tailored blanks).