Monitoring Techniques

Monitoring Techniques

For processes in the area of series production, monitoring the forces needed to manufacture the parts is the most suitable solution. Easy to install piezo-electric sensors measure the loads on the tools such as forming forces, cutting forces or feed forces. The real power consumption of electric drive motors is also used for monitoring.

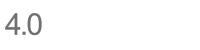

In a learn cycle, the monitoring systems automatically memorize the typical force pattern as nominal curves for the parts that are currently running. The curve of each subsequently manufactured part is compared to the learned nominal curve and monitored for limit violations using various methods. Impermissible deviations lead to the immediate shutdown of the machine in order to avoid further defective parts and to protect machine and tool against overload. Alternatively, sorting gates are activated which automatically separate defective parts. Sophisticated algorithms ensure that even minor errors are reliably detected, while at the same time unnecessary machine shutdowns are avoided.

These are the techniques you can rely on: